Driving your car with engine hesitation or slow acceleration is not only infuriating, it can also be dangerous when overtaking or when crossing an intersection. Sluggish acceleration is a symptom of an underlying problem with your vehicle, which must be resolved urgently before it does more damage to your vehicle.

The most common causes for slow acceleration are clogged air filter, dirty mass air flow sensor (MAF), clogged fuel filter, fuel pump malfunction, faulty oxygen sensor, dirty throttle body, worn spark plugs and clogged catalytic converter. Less common causes are faulty throttle position sensor (TPS), bad ignition coils, dirty fuel injectors, clogged engine oil filter, transmission problem, worn piston rings and blown head gasket.

1. Clogged air filter

If the air filter is dirty in your vehicle, it can have a negative effect on the performance of the engine, as less air passes through the dirty filter which suffocates the engine. This ultimately also increases fuel consumption. In the worst case, the engine can stall if the air filter is extremely clogged.

Replacing the filter takes a few minutes and does not require any special knowledge. So this is the first thing you should check.

2. Dirty or faulty mass air flow sensor (MAF)

Defective or dirty mass air flow sensor (MAF) can result in loss of power, uneven engine running, erratic idling, misfires, poor exhaust emission values including black smoke. The mass air flow sensor is part of the engine’s intake system and is located between the air filter box and the throttle valve. It is not only important for power delivery in your vehicle, but also for the lowest possible pollutant emissions.

What happens when MAF sensor malfunctions?

If the MAF sensor is defective or dirty, it does not send correct measured values to the engine control unit. The optimal amount of fuel can no longer be calculated which results in either too little or too much fuel injected into the combustion chambers. The engine runs too “lean” or too “rich”. This can cause the engine warning light to illuminate in the instrument cluster and the fault can be read out by a diagnostic device.

What causes MAF sensor to fail?

The mass air flow sensor is a wearing part. As the mileage of the vehicle increases, it can happen that increasingly inaccurate values are sent to the engine control unit. With a noticeable loss of performance and high mileage, a defective MAF sensor should definitely be considered. However, the sensor can also malfunction earlier. When driving fast in heavy rain, water can occasionally pass through the air filter, which can severely impair the function of the MAF sensor. In rare cases, the MAF sensor can also be damaged by oil vapors flowing back out of the crankcase ventilation after the engine has been switched off.

How to check if the MAF sensor is bad?

Reading out the fault codes using a diagnostic device is relatively reliable. If you see P0100, P0101, P0102, P0103 or P0104 code in the OBD2 scanner, it indicates a problem with the mass air flow sensor. However, it can happen that there are no error codes. In case of doubt, the sensor may have to be replaced. But this should only be done after an extensive analysis as the MAF sensor may not be responsible for the symptoms of poor acceleration in your vehicle.

Can I clean a dirty MAF sensor?

In some cases, cleaning the mass air flow sensor can help the sensor measure the correct values again. However, caution is advised here, as the sensor parts are very sensitive to touch. Find the location of the MAF sensor in your vehicle, unplug the electrical connectors, and remove the sensor from the housing. Spray at least 10 spurts of MAF cleaner onto the sensor and then let it air dry for an hour or until completely dry. Do not use cloth or cotton swabs to clean the sensor, as it can damage it.

Recommended video:

Note (MAP Sensor): If you can’t find MAF sensor in your vehicle, it is possible your vehicle may not have one, especially if its an older vehicle. Instead, the air mass flow rate is calculated by the control unit using the data from the MAP sensor. A faulty MAP sensor presents more or less the same symptoms as a faulty MAF sensor.

3. Clogged fuel filter

If the fuel filter is clogged in your vehicle, not enough fuel can get into the engine. This causes loss of power and jerking of the vehicle when accelerating. In worse case scenario, engine cuts out while driving due to insufficient fuel supply.

If this happens, the control unit can detect the lack of fuel problem and the engine check light will illuminate in your vehicle. You may see error code P0087 when you connect OBD2 scanner to your vehicle, which indicates a fault within the fuel delivery system.

How does the fuel filter get clogged?

The fuel filter is designed to prevent rust particles and other debris from your vehicle’s fuel tank from getting into the engine, where they would cause expensive damage. If you don’t follow the maintenance schedule of your vehicle and don’t change the fuel filter on time, the permeability of the filter drops and so does the fuel pressure in the engine. To a certain extent it does not matter, but if the fuel filter becomes too dirty, the engine performance will be reduced.

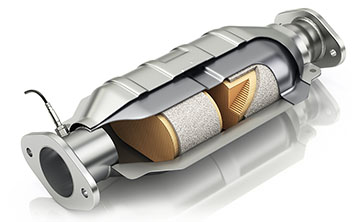

4. Clogged catalytic converter

The catalytic converter is part of the exhaust system in your vehicle and its main purpose is to convert exhaust gases that are harmful to health and the environment into less harmful byproducts. Over time, toxins accumulate and clog up the catalytic converter, especially if the vehicle has racked up a lot of miles.

What are the signs of bad catalytic converter?

Common signs of clogged catalytic converter are irregular running of the engine, unusual exhaust gas odor, poor fuel economy, engine check light illuminates, limited performance above a certain speed or loss of performance, and sometimes rattling noises.

How long does a catalytic converter last?

There are many factors that affect its service life, but typically the catalytic converter should last between 70,000 and 100,000 miles. However, it can fail much earlier due to other faults, for example: misfires in the engine, bad air-fuel mixture, faulty oxygen sensor or coolant in the combustion chambers can lead to catalytic converter failure.

5. Faulty oxygen sensor

The oxygen sensor monitors the level of pollutants in the engine’s exhaust gases and reports the data to the control unit that continuously adjusts the air to fuel ratio in the engine. If the oxygen sensor develops a fault, it will send incorrect readings to the control unit which can result in slow acceleration, loss of power, irregular idling, engine hesitation, or stalling.

Can a bad O2 sensor lead to catalytic converter failure?

Faulty oxygen sensors are the leading cause of catalytic converter failures. If you suspect a problem with O2 sensor, you should act immediately and get it checked by a professional mechanic. O2 sensors are relatively cheap compared to the price of catalytic converters, which can easily cost you over a thousand dollars to replace.

How to check for faulty oxygen sensor?

If there is any fault in the oxygen sensor, it usually illuminates the engine check light in the instrument cluster of your vehicle. You can diagnose the problem by connecting an OBD2 scanner to your vehicle. If you see any error code from P0130 to P0135 or from P0150 to P0155, it indicates a problem with the upstream oxygen sensor.

Recommended video:

6. Dirty throttle body

Dirty throttle body can also be the cause of slow acceleration in your vehicle. The common signs of dirty throttle body are poor engine performance, erratic idle, the engine react poorly to movements of the accelerator pedal, and the engine sputters or stalls.

One of the main causes of a faulty throttle is internal contamination. The throttle valve regulates the supply of air to the internal combustion engine. Over time, dirt and grime that escapes through the air filter can accumulate in the throttle body, this results in improper throttle valve movement, which causes problems with the control of the air supply.

7. Faulty throttle position sensor (TPS)

The throttle position sensor or TPS is used to determine the opening angle of the throttle valve. The information obtained is sent to the control unit and contributes to the calculation of the amount of fuel required. The symptoms of defective throttle position sensor are usually reduced engine performance, engine jerks, RPM fluctuations when idling and a slow drop in speed after the driver has released the accelerator.

If you see any error code from P0120 to P0124 on OBD2 scanner, it indicates a problem with the TPS sensor.

8. Fuel pump malfunction

The fuel pump in your vehicle is like a beating heart that pumps fuel to the engine when the vehicle is running. A malfunctioning fuel pump can result in irregular or decreased acceleration, poor engine starting behavior, engine jerking or stalling while driving and a decrease in fuel efficiency.

Common causes of a defective fuel pump are leaks or contamination within the pump, this can illuminate the engine check light in your vehicle. Diagnostic codes that a bad fuel pump can trigger are P0230, P0231, P0232 and P0087.

9. Bad spark plugs or ignition coils

If the spark plugs are not generating sparks properly, the engine will no longer run optimally. This is often noticeable in a loss of performance and increased fuel consumption. You may also notice that the engine is not running smoothly or the engine is jerking while driving – sometimes the engine simply cuts out. If you continue to drive with a defective spark plug, you run the risk of very expensive consequential damage, for example catalytic converter failure.

The ignition coils are part of the ignition system and are responsible for amplifying the relatively low battery voltage from 12V to a high voltage of tens of thousands of volts for the spark plugs. A fault in an ignition coil can cause poor sparking which can result in poor engine performance. The symptoms of a bad ignition coil are more or less the same as a bad spark plug.

10. Dirty fuel injectors

Fuel injectors are part of the fuel delivery system that sprays fuel in the form of a high-pressure mist. Over time they can get clogged due to hydrocarbons, sediment and other elements in the fuel. When that happens, proper amount of fuel can no longer be delivered to the combustion chamber at the correct pressure.

Common symptoms of clogged fuel injectors are slow acceleration, rough idling, irregular engine performance, increased fuel consumption, engine hesitation and misfiring.

Is it safe to use fuel injector cleaners?

Cleaning the fuel injector nozzles using fuel additives almost always leads to an improvement in the injection behavior, since the additive dissolves the deposits on the nozzles. But before using your preferred injection system cleaner in your vehicle, it is recommended to find out if its approved by the manufacturer in advance. Because the additive is poured into the fuel tank and gets through the entire fuel system and the engine. Some injector cleaners can cause damage to the oxygen sensor.

11. Clogged engine oil filter

The engine oil filter in your vehicle ensure that the engine oil remains free of dirt particles, metal shavings, soot or unburned fuel, thus preventing damage. If the filter becomes clogged, it can cause the engine to sputter, the faster you drive, the more it sputters.

Although most oil filters have a bypass valve or pressure relief valve, which activates when the filter becomes clogged after it has not been replaced in time, but in rare cases the bypass valve can fail.

12. Transmission problem

A malfunction in the transmission can also be responsible for slow acceleration problem in your vehicle. Transmission is a complex component, it is responsible for transferring the power from the engine to the wheels. There are many gears that mesh with one another. Sooner or later this friction leads to wear on the components, especially if your vehicle has racked up a lot of miles or if you didn’t change transmission fluid in time.

A faulty transmission usually show other signs including grinding or clunking noises, jerky acceleration and burning smell.

13. Worn piston rings or valve seals

The piston rings are sealing element on pistons of the internal combustion engine. The purpose of both valve seals and piston rings is to keep engine oil out of the combustion chamber. When the piston rings are worn or damaged, the combustion chamber of the engine loses pressure. This results in reduced engine power as the piston is unable to fully compress the fuel and air mixture.

The most common symptoms of worn piston rings are: blue colored smoke comes out of the tailpipe, a lack of acceleration power, excessive oil consumption and engine misfires.

14. Blown head gasket

The head gasket is responsible for providing the seal between the engine block and cylinder heads. Its purpose is to seal the combustion gases within the cylinders and to avoid coolant or engine oil leaking into the cylinders. Leaks in the head gasket can cause all sorts of problems including poor engine performance and/or overheating.

Common signs of leaking head gasket are white smoke coming out of the tailpipe, coolant level going down as it burns in the engine, oil in coolant bottle, and milkshake color oil in engine due to mixing of oil and coolant.

How to check if head gasket is leaking?

You don’t have to go to a workshop to check for a leaking head gasket. There are test kits available in the market in which you just have to insert a tube filled with colored liquid in the radiator (in place of the radiator cap), and then start the engine. If the liquid changes color, then there is a leak in head gasket.

Use OBD2 scanner for diagnosis

Most modern vehicles are equipped with on-board diagnostics (OBD), a fault diagnosis can provide initial indications of where the malfunction is located.

To begin troubleshooting, you must first connect the diagnostic tool to your vehicle. The OBDII connector is usually located under the dashboard. With the tool connected, turn on the ignition. Most diagnostic devices then ask for some information about the vehicle. It is important that you enter this 100% correctly, otherwise the result of the search may be inaccurate. In addition to the vehicle make, model, and engine type, you usually also have to type in the Vehicle Identification Number (VIN). Since some OBD codes are manufacturer-specific, the scanner will be able to give you more accurate information if you enter more details about your vehicle.

Conclusion

There are many reasons why your vehicle is not accelerating properly. When looking for the reason, you should always start with the most obvious causes, problem with air intake or fuel supply.

In any case, it is advisable for laypersons to visit a workshop. A professional mechanic can swiftly diagnose the sluggish acceleration issue for you.