Volkswagen Navarra is using its 3D printer, normally dedicated to creating work tools for the production process of the Volkswagen Polo and Volkswagen T-Cross , to manufacture protective screens against the coronavirus and has already delivered the first 1,000 units.

Since last March 23, Volkswagen Navarra has been producing, in two work shifts, 130 protective screens per day , which are subsequently disinfected in the factory and made available to professionals in the health sector in Navarra.

Following the indications of NAITEC (Technological Center for Automotive and Mechatronics) and the criteria established by the Government of Navarra, the College of Nursing of Navarra, the College of Physicians, COIINA (Official College of Industrial Engineers of Navarra) and the NGO SAR (Salvage, Help and Rescue), Volkswagen Navarra has already manufactured 1,000 units of protectors and will continue to collaborate with the requests of the Regional Government.

The Volkswagen Navarra team that works in the manufacture of the protective screens is made up of five professionals from the Factory’s Technical Product Area: Javier Cuartero García (head of assembly and workshop in Pilothalle), Iñaki Irigoyen Urra, Iosu Arraya Ayechu, Gorka Eliceche Elizagoyen and Iker Resa Ahechu.

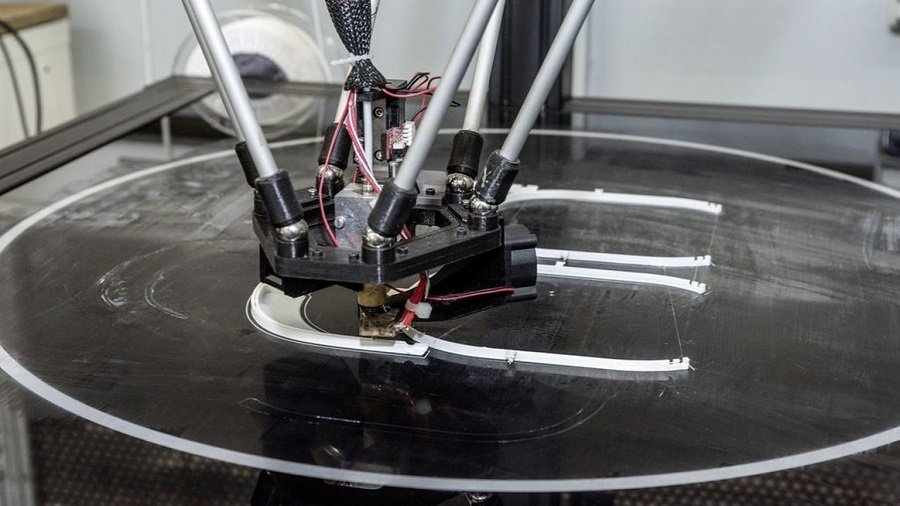

“First we print the visors . They are made with PA12, a hard nylon-like material. Each cycle of this 3D printer, from the HP brand and with Multijet Fusion technology, allows us to print 130 units and it takes about 16 hours, to which we must add another 5 hours for cooling the visors. Later, with the acetates provided by the MKM company, we work the screens that are attached to the visors. We make four holes with a drill and round off their corners. Finally, we incorporate the rubber bands that the Municipal Police of Pamplona have provided us with,” Cuartero explains.

Disinfection and distribution process

After completing the manufacturing process, the protective screens are disinfected on the Volkswagen Navarra premises, specifically in a disinfection booth built in the factory for this project with wood and polycarbonate, using a borrowed ozone generation machine, by the ISN firm. This work is carried out by Asier Martorell Aguirre, Manager of Factory Planning, and Iban Vicente López, Head of Firefighters at Volkswagen Navarra.

“Throughout the process, we follow the instructions validated by NAITEC, disinfecting and packaging the protection screens , ten by ten, in heat-sealed bags. Subsequently, we deliver them at the headquarters of the Municipal Police of Pamplona to the NGO SAR, which channels the requests from hospitals and residences in Navarra and, with the help of the different police forces and according to the instructions of the College of Nursing of Navarra, distribute the available units,” explains Martorell.

House of Mercy and ASVONA

In recent days, Volkswagen Navarra has donated 350 masks and 50 liters of alcohol to the House of Mercy in Pamplona, and has transferred a Volkswagen Caddy from its Vehicle Park to the Association of Volunteers of Navarra (ASVONA), for use in the distribution of food to the homes of the elderly, disabled, people with reduced mobility, etc.