Tesla, Inc. (formerly called Tesla Motors) is an American company located in Silicon Valley, California, and led by Elon Musk that designs, manufactures, and sells electric cars, components for electric vehicle propulsion, and large-scale household batteries. It is based in Palo Alto, California.

It was founded in July 2003, by Elon Musk, JB Straubel and Martin Eberhard. Elon Musk had already founded several companies, was a millionaire and had the idea to develop batteries for the storage of renewable energy. The company name is a tribute to Serbian-born electrical engineer Nikola Tesla.

Overview

The core of the company is in the engineering of the electric vehicle propulsion system that includes: battery pack, motor, power electronics and control software that allows all components to form a system. The modular design allows components to be reused on different Tesla and third-party models. The system is very compact and contains far fewer moving parts than an internal combustion engine. Tesla Motors uses three-phase induction motors that incorporate a copper rotor and copper windings optimized to reduce resistance and energy loss. Tesla developed fundamental patents for its manufacturing. Power electronics govern the input and output current flow of the battery pack, controls the generation of motor torque while driving and recharges the battery pack when connected to an outlet.

Tesla Motors designed one-gear gearboxes for the Roadster and Model S. They combine low weight with high efficiency to match the speed and torque of AC induction motors. They are manufactured at the Tesla plant. Electric vehicles contain many processors to control safety and power functions. Tesla Motors builds the firmware for many processors with algorithms that control traction, vehicle stability, acceleration, regenerative braking, the state of charge of each cell in the battery pack, and safety systems.

Tesla Motors carries out the design and engineering of the body, chassis, interiors, heating and air conditioning systems. Some subsystems of a traditional car must be redesigned into an electric vehicle. For example, Tesla Motors redesigned the climate control system to integrate it with the battery pack temperature management system.

As of December 31, 2011 Tesla Motors had 59 patents awarded and another 230 patents pending approval. Patents will begin to expire in 2026. On June 12, 2014 Tesla Motors released all its patents. Tesla Motors’ earnings as of December 31 were $111.9 million in 2009, $116.7 million in 2010 and $204.2 million in 2011. Tesla Motors had a net loss in 2011 of 254.4 million and a net cumulative loss of 669.4 million dollars till 31 December 2011.

Master plan

Tesla was founded to accelerate the transition to sustainable transportation. Tesla in the beginning wrote its “master plan” to influence the industry from a point of view based on renewable energy. Its main objectives were:

- Start with a small project by manufacturing few units at a high price. It was the Tesla Roadster. It demonstrated that a high-performance electric car could be manufactured that dispelled the myth that electric vehicles were slow, heavy, ugly and with little battery range. Tesla went on to manufacture up to 500 units a year. It had a big effect on the industry, and Bob Lutz, former president of General Motors claimed that the Tesla Roadster was responsible for starting the Chevy Volt program, which in turn influenced the Nissan Leaf program .

- Manufacture a vehicle in greater volume of units and at a cheaper price. The Tesla Model S proved that it could compete with the large luxury saloons. On the same platform Tesla built the Tesla Model X.

- Vehicle produced in large volume and at an affordable price. The benefits Tesla obtained with the previous models allowed it to tackle the Tesla Model 3 project. On the same platform Tesla manufactured the Tesla Model Y.

History and financing

Founding of Tesla Motors

The idea of founding a company that commercialized electric cars was born in 2003, when General Motors announced that it would withdraw all units of the EV1, and scrapped them. The company AC Propulsion had two teams working on the development of an electrical prototype, the T-Zero; on one team were Martin Eberhard, Marc Tarpenning and Ian Wright, and on the other team were Elon Musk and JB Straubel. The objective of creating cars powered by renewable energy seemed unfeasible due to the multiple problems involved (poor range, recharge time, price of batteries, lack of infrastructure, and apparent lack of attractiveness for customers, as General Motors stated when it left the electric car project).

Tom Gage, president of AC Propulsion, proposed that both teams join forces if they wanted to give viability to their developments, and the duo Elon Musk and JB Straubel joined the trio with the union of Martin Eberhard to found Tesla Motors. Elon Musk had already founded several companies, was a millionaire and had the idea of developing batteries for the storage of renewable energy since he studied in Stanford, so they had a clear goal.

Elon Musk’s funding

Musk would contribute the necessary money to carry out the idea and would be responsible for design, Martin Eberhard was selected as CEO and JB Straubel as CTO. The first round of funding raised $7.5 million, most of it from Musk’s pocket. Other investors were Compass Technology Partners, SDL Ventures, and other private investors. In the second round, Musk invested $13 million.

First prototype

In the early years, Eberhard was in charge of the business, while Musk supervised the design of the car and Straubel was responsible for the mechanics of the vehicle. Thus they brought out the first prototype called Tesla Roadster, a prototype based on the Lotus Elise. The Tesla differed in motorization, and in Musk’s personal insistence that the bodywork should be carbon fiber rather than fiberglass like that of the Lotus Elise.

In May 2006, in the third round of $40 million, Musk invested together with other investors attracted by the company’s ideas. The objective was to demonstrate that the electric vehicle could compete with the best sports car brands; and with the funds obtained from the sale of the first car they would develop affordable vehicles.

The awards

In August 2006 they published on their website the plan they wanted: to design a high-performance sports car. In October of that year they received the Global Green 2006 award in an act chaired by Mikhail Gorbachev for the design of the Tesla Roadster, again recognized in 2007 with the Index Design award. In May 2007, the fourth round added another $45 million, accumulating a total of $105 million in investments.

Financial problems

The past two years had shown that they were serious on a technical level, but the executive situation was not stable due to financial problems. In June 2007, at a company meeting, Martin Eberhard said that the unit production of the Tesla Roadster would exceed $100,000, not the $65,000 they had planned.

A small Tesla investor, the CEO of Flextronics named Michael Marks, was temporarily appointed CEO of Tesla Motors by Elon Musk to replace Eberhard, being replaced in December 2007 by Ze’ev Drori, founder of an electronics company. Martin Eberhard and a dozen top executives were dismissed in January 2008. Tesla was forced to cut the workforce by 10% because spending in 2007 was out of control.

NHTSA bailout

In January 2008, the financial contribution of NHTSA, an agency dependent on the United States government, saved Tesla from bankruptcy, contributing $43 million to a company that had been making losses since its creation. The fifth round of financing in February 2008 added another $40 million. Of the $145 million, the company had received, $74 million came from Elon Musk.

Elon Musk as CEO

In October 2008, Tesla Motors was unable to raise the $100 million it needs to survive, so Musk took over as CEO and Ze’ev Drori becomes Vice President until he left the company in December. The delay in the Model S led to the dismissal of a quarter of the employees and the closure of the Michigan engineering office. Darryl Siry, Tesla’s Director of Sales, resigned saying he was uncomfortable with how the company financed its operations. He said he felt the company was chronically underfunded and undercapitalized.

In January 2009, Elon Musk said Tesla would deliver benefits starting in the second half of that year. All this thanks to a grant from the United States Department of Energy to build a car factory, which would be delivered to them in the summer.

Daimler AG investment

When the situation was worse, Daimler AG acquired almost 10% of the shares of Tesla Motors for an amount of about $50 million in the month of May 2009. Tesla Motors and Daimler AG agreed to cooperate on battery systems, propulsion for electric vehicles and vehicle projects. As part of the collaboration Prof. Herbert Kohler, Vice President of E-Drive and Future Mobility from Daimler AG, had a seat on the Tesla board of directors. In 2014 Daimler terminated the supply contract with Tesla and sold its shares for $780 million. In July 2009, AABAR AD bought 40% of the shares from Daimler AG.

US Department of Energy loan

In June 2009, the US Department of Energy approved the delivery of a $465 million loan, which was part of a $8 billion program for advanced vehicle technologies. The low-interest loan was part of the Advanced Technology Vehicles Manufacturing Loan Program (ATVM), created in 2007 during George W. Bush’s tenure to power more efficient vehicles and reduce dependence on foreign oil. This money meant the rescue of Tesla Motors. The loan was intended for the engineering and production of the Model S and the development of electrical technology that Tesla sells to other manufacturers.

Further investments

In September 2009, Tesla announced another round of financing of $82.5 million in which Daimler AG, Fjord Capital Partners, Aabar, among others, invested. It was the first round of funding in which Elon Musk did not contribute. To date, a total of $783.5 million had been invested in the company. In July 2011 Tesla Motors signed a production contract with Lotus Carsto to produce “gliders” (complete cars without batteries, motor or electric propulsion components) for Tesla. The production contract was extended to keep the Roadster in production until December 2011 with a minimum number of 2,400 units.

IPO

On January 29, 2010, it applied for the IPO managed by Goldman Sachs, Morgan Stanley, JP Morgan and Deutsche Bank Securities. On March 26, Tesla claimed that it had sold 937 Tesla Roadster to customers in 18 countries and had generated a profit of $126.8 million through December 31, 2009. On May 21, 2010 Tesla announced a strategic collaboration with Toyota, which would buy $50 million in Tesla Motors stock.

On June 29, 2010 Tesla Motors went public on the NASDAQ under the acronym TSLA. The public offering raised $226 million for the company. It was the first American automaker to go public since 1956 after Ford Motor Company.

Stock market evolution

On June 29, 2010 it went public at $17. Until December 31, 2011, the minimum price was $ 14.98 and the maximum was $ 36.42. On December 2, 2012, the stock was worth $33.82 and the market value was $3,848,001,214. On August 28, 2013 the share was trading at $166 and the market capitalization was $20,215,293,743. On September 9, 2014, the share was trading at $278 and the market capitalization was $34,706,910,603. On May 14, 2018, the share was trading at $299 and the market capitalization was $51,530,000,000.

On January 15, 2019 the share was trading at $302 and the market capitalization was $ 51,910,000,000. At the beginning of April 2017, it had a market capitalization of around 47.8 billion dollars, thus surpassing the valuation of Ford Motor Company (44.9 billion). Throughout 2017, it was the automobile company that increased its brand value the most according to the BrandZ index.

Brand strategy

Until May 2008, Tesla Motors sold its cars by phone, internet or at headquarters. Then opened the first store in Los Angeles, California. In 2012, it had 20 stores and workshops in North America, Europe and Asia. Tesla stores are located in luxury sectors of major cities. Some combine a shop with a service workshop.

Tesla Motors aims to provide the customer with a compelling experience while achieving sales and service benefits that traditional manufacturers do not have in the franchise and shop model. Customers deal directly with Tesla staff and not with franchisees. Tesla wants to achieve better inventory cost control, warranty management, service, brand strengthening, and customer feedback. Being the owner of the Tesla commercial network avoids the conflict of interest in the structure of traditional dealerships where the sale of parts under warranty and repairs by the dealer are a benefit for the dealer and an expense for the manufacturer.

George Blankenship , director of sales for Tesla Motors, said: “We don’t want to sell a car to people, we want people to buy our car because they want to. I believe that anyone who comes to a Tesla store today will want to buy a car in the next 10 years. That is the important thing, not the next 3 days, but the next 10 years.”

Unlike other manufacturers, there is no price negotiation because it is fixed for the entire United States and is published on its website. The customer can focus on configuring it with their preferred options.

Tesla Motors does not have a warehouse for manufactured cars to sell, but instead manufactures the cars as configured by the customer at a Tesla store or online.

On June 12, 2014 Tesla Motors announced that it was releasing all of its patents.

Discontinued models

Tesla Roadster

The first car of the company was the Tesla Roadster, it is the first series car that using lithium-ion batteries achieves a range of more than 200 miles (322 km) per charge. The base model accelerates from 0 to 60 miles per hour (97 km/h) in 3.9 seconds and according to Tesla Motors’ environmental analysis is twice as efficient as the Toyota Prius . The final price of the 2009 basic model was $109,000. As of June 2012, 2,100 Tesla Roadsters had been sold in 31 countries and had traveled over 37 million electrical kilometers. The Tesla Roadster appeared on the cover of Time. Tesla stopped taking orders for the Roadster in August 2011.

Tesla Roadster Sport

The Tesla Roadster Sport was an enhanced version of the sporty Tesla Roadster. Tesla began accepting orders for the Roadster Sport in January 2009. It accelerates from 0 to 60 miles per hour (97 km/h) in 3.7 seconds, compared to the Roadster’s 3.9 seconds. The price of the Roadster Sport started at $128,500 in the US and 112 000 euros (excluding taxes) in Europe. Deliveries started in July 2009.

Models in production

Tesla Model S

The Tesla Model S is an electric liftback manufactured by Tesla Motors, deliveries began in July 2012. The annual production is 50,000 units. It can accommodate 5 adults. It has a EPA rated range 390 miles, and accelerate from 0 to 60 mph in 2.3 seconds.

Recharging times vary depending on the state of charge, its total capacity, the available voltage and the amperage of the recharging current. From a 240 V, 20 kW and high amperage socket, the range can be increased by 60 miles for every 45 min charge, this is equivalent to about 5 hours to fully recharge the 85 kWh battery.

The rear-wheel drive version has an electric motor with a gearbox, while the all-wheel drive version equips two electric motors with a gearbox each. The battery pack is flat and is under the car. It is made up of thousands of lithium ion batteries with a capacity of 60 kWh, 75 kWh, 90 kWh or 100 kWh depending on the version. The body is aluminum reinforced with elements of boron steel.

The federal government of the United States subsidizes this vehicle with 7,500 USD. Additionally, some states subsidize it with another 10,000 USD, up to a total of 17,500 USD. In Europe the price without extras ranges from 69,840 euros to 104,740 euros before taxes and subsidies. As of June 2015, all Tesla Model S had traveled a cumulative distance of 1 billion miles (1,609 million km).

Tesla Model X

The Tesla Model X is an electric SUV manufactured by Tesla Motors based on the Model S platform. It began its deliveries in the US market on September 29, 2015. The Model X is a mixture of minivan and SUV (Sport Utility Vehicle) with capacity for 7 adults. It uses the same platform as the Model S. It claims to be more functional than a minivan, more attractive than an SUV and with more features than a sports car. The rear doors are of the Falcon wings type and open upwards. This allows better accessibility to the rear seats. The battery pack is flat and is under the ground. The battery capacity is 60 kWh, 75 kWh, 90 kWh or 100 kWh.

The Model X is equipped with two motors with a single-speed gearbox each, one set on the front axle and one on the rear, providing all-wheel drive. The acceleration from 0 to 100 km/h of the base model is 6.2 seconds, while the Model X P100D Sig does it in 3.1 seconds with “Ludicrous Mode”, being the fastest SUV in the world.

The Tesla Model X was designed by Franz von Holzhausen. The chassis, body, engine, and power storage are Tesla Motors’ own. It has a drag coefficient of 0.24 making the Model X the most aerodynamic SUV on the market. The Telsa Model X was presented in February 2012.

Tesla Model 3

The fourth model Tesla has marketed since July 28, 2017 is the Tesla Model 3, with a base price for the Standard version of $35,000. It has a range greater than 220 miles according to the EPA cycle. Acceleration from 0 to 60 mph is 5.6 seconds in the basic version.

The base model has supercharging enabled and hardware for the Autopilot power steering feature. It can carry five passengers in comfort. It has a trunk behind and a smaller one in front with a load capacity greater than any other car of similar size. It can house a 210 cm surfboard inside. It received five stars in all safety tests and in all categories. It has a panoramic glass roof.

About 500,000 units will be manufactured each year at the Tesla factory in Fremont, California. The lithium-ion batteries are manufactured at its Tesla Gigafactory 1 in Reno, Nevada. It is the factory with the largest plant area in the world and the second in volume after Boeing in Washington. It makes more lithium-ion batteries than the rest of the world’s factories combined.

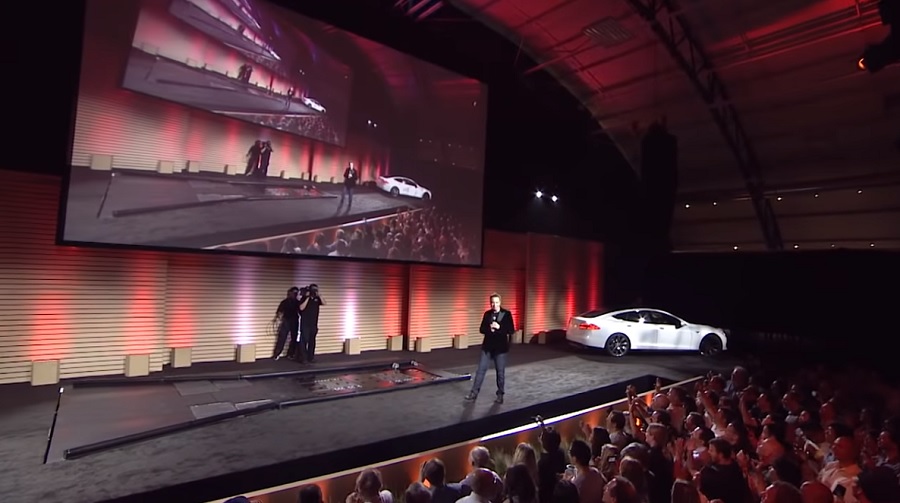

On March 31, 2016, during the official presentation, it announced that 115,000 units of the Model 3 had already been reserved. Tesla stated that in the first 24 hours it received more than 180,000 reservations, which was a world record for sales of any type of product. On the second day, reservations exceeded 232,000. In the first week, it received 325,000 reservations. That meant future sales of $14 billion. Tesla claimed it was the largest launch of any type of product made in a week. Tesla delivered 50,658 vehicles in 2015 and 14,820 in the first quarter of 2016. Each reservation involved the payment of $1,000 (recoverable in the event of cancellation).

Initially the Model 3 was to be called Model E but Ford had that name registered and refused to assign the rights to Tesla. Tesla named it Model 3 but writing the number as Model “☰” with three horizontal stripes just like Tesla’s E on its logo; in this way with the different models the word S3X is formed. Elon Musk registered the name Model Y for a future crossover version of Model 3. Then the word “SEXY” was be formed with all four Tesla models.

Tesla Model Y

The Tesla Model Y is a crossover electric compact developed by Tesla Inc. The market launch was scheduled for fall 2020, was introduced on March 14, 2019. Production began in January 2020 and deliveries began on 13 March 2020. Sales in Europe start in early 2021.

It has 5 to 7 seats. It has one or two electric motors and can have AWD four-wheel drive. Acceleration from 0-60 mph takes place between 3.7 seconds and 6.3 seconds. The top speed ranges from 193 km/h (120 mph) to 241 km/h (150 mph). It has an EPA rated range of 370 km (230 miles) for Standard Range, to 483 km (315 miles) for Long Range. It closely resembles the Tesla Model 3 with which it shares 75% of the parts.

Upcoming models

Tesla Roadster 2020

In November 2017, Tesla presented a new version of the discontinued Roadster that is scheduled to be released in 2020. It is a four-seater supercar. Top speed of 250 mph. 0-60 miles per hour in 1.9 seconds. 0-100 miles per hour in 4.2 seconds. 1/4 mile in 8.8 seconds. 200 kWh battery. Autonomy of 1000 km. It will be priced at $200,000.

Tesla Semi

In November 2017, Tesla introduced a truck model that can load 36 tons. The first deliveries are planned to be made in 2019. It has four electric motors. Accelerates from 0 to 60 mph at full load in 20 seconds. You can climb slopes of 5% at 65 mph (105 km/h). Driving range of 300 to 500 miles (480 to 800 km) at full load. It will have a guarantee of 1 million miles (1.6 million km). It will have advanced autonomous driving functions and the electronic control of its four independent motors prevents the scissor effect.

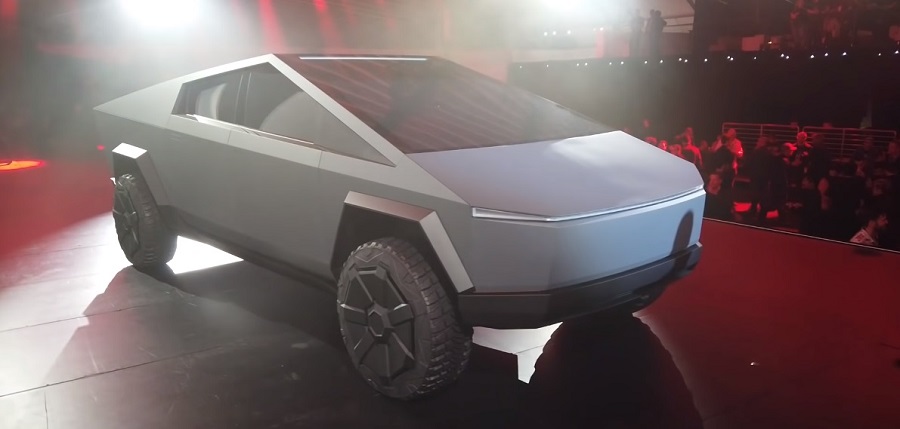

Tesla Cybertruck

The Tesla Cybertruck is a 4-door 6-seater light commercial electric vehicle from the American manufacturer Tesla Motors presented in November 2019. Three versions were announced with driving range of 250–500 miles (400–800 km) and accelerations from 0-60 mph between 2.9 and 6.5 seconds. Tesla’s goal in developing the Cybertruck is to provide a sustainable substitute for the 6,500 pickups that are sold every day like hot cakes in the United States.

The base price for the rear-wheel drive version will be $39,900 and four-wheel drive models will start at $49,900.

Sales are slated to begin in late 2021.

Two days after the presentation, Elon Musk announced on Twitter that 146,000 reservations had been made; 42% two engines, 41% three engines and 17% one engine.

Tesla Cyberquad

The Tesla Cyberquad is an electric four-wheeled off-road vehicle created by Tesla, Inc., and exhibited at the Tesla Cybertruck presentation in Hawthorne, California, at the Tesla Design Studio. At the end of the presentation, Elon Musk announced ‘one more thing’, at which point the ATV was shown to be loaded on the back of the Cybertruck.

It is not listed on the Tesla website, however it is mentioned in the Cybertruck specs, mentioning “Room for your Toolbox, Rim and Cyberquad, with room to spare.” On November 22, 2019, Elon Musk tweeted, “The Tesla 2-Person Electric ATV will come first as an option for Cybertruck.” The price was not mentioned. The trademark “Cyberquad” was registered in November 2019.

Storage systems

Powerwall and Powerpack

On April 30, 2015, Tesla introduced two energy storage systems: Powerwall and Powerpack. The Tesla Powerwall is a lithium-ion battery pack used as a backup in a household’s electrical grid that can store electrical energy from renewable energy generation, such as solar or wind installations, or store electricity at night when electricity is cheaper. Can be installed outdoors or indoors and does not require a closed room. It also allows for electrical installation in remote locations without network access.

Tesla offered two capacities: 7 kWh and 10 kWh. Its price was $3,000 and $3,500 respectively. They can deliver 5 kW of continuous power and peaks of up to 7 kW. The current supplied varies from 5.8 nominal amps to 8.6 maximum amps. They weigh 100 kg and their dimensions are 1300 mm x 860 mm x 180 mm. They have a temperature control and liquid cooling. The Powerwall does not include the DC-AC inverter. Tesla designed these batteries in a modular way. Up to 9 packages can be connected for a total capacity of up to 90 kWh. Tesla offers a 10 year warranty.

On October 28, 2016, Elon Musk introduced Powerwall 2 priced at $5,500. You can supply a 2-bedroom house for one day and if you have enough solar panels you can do it indefinitely. It has a capacity of 14 kWh (usable 13.5 kWh). It can deliver 5 kW of continuous power and peaks of up to 7 kW. It weighs 120 kg and its dimensions are 1150 mm x 755 mm x 155 mm. It has a temperature control and liquid cooling. The powerwall 2 includes an internal DC-AC inverter. It is scalable up to 9 units and has a 10 year guarantee. It can be mounted indoors or outdoors, on the floor or hung on the wall.

Tesla offers the 100 kWh capacity Powerpack that can be scaled indefinitely to GWh capacities.

On October 28, 2016 Elon Musk presented the Powerpack 2 with a capacity of 210 kWh and an output of 50 kW. It can be scaled indefinitely to reach GWh capabilities. It integrates directly into the electrical network. At that time Southern California Edison was building an 80 MWh facility with that system. Another 52 MWh facility was under construction in Hawaii.

Tesla will release patents on its energy storage systems following its open source policy. The Powerwall and Powerpack storage units were manufactured at the Tesla factory in Fremont during 2015 and at Tesla’s Gigafactory 1 in Reno, Nevada, since 2016. The first deliveries were made in July 2015.

According to Elon Musk, to cover the sustainable energy generation in the United States, only 160 million Powerpacks would be needed for a total of 16,000 GWh. And for the whole world 900 million Powerpacks would be required for a total of 90,000 GWh. To cover power generation, transportation and heating worldwide, 2 billion Powerpacks would be needed for a total of 200,000 GWh.

As of May 7, 2015, 38,000 Powerwall units and 2,500 Powerpack units had been reserved, with a total of 63,000 Powerwall units, for a total value of $800 million. As of July 2015,100,000 units had already been reserved for a total value of $1 billion.

Solar Roof

In the fall of 2016, Tesla Motors began the merger process with SolarCity, which is dedicated to the installation of photovoltaic solar panels.

On October 28, 2016, Elon Musk presented the Solar Roof. It is a system of glass tiles that incorporate photovoltaic cells. Musk noted that they were beautiful, affordable, and integrated with the home providing better insulation. They have a higher impact resistance compared to clay or slate tiles. It introduced the Textured Glass Tile, Slate Glass Tile, Smooth Glass Tile and Tuscan Glass Tile models.

Collaborations with other manufacturers

Mercedes A-Class E-Cell

As part of its collaboration with Mercedes-Benz, Tesla manufactured engine components for the Mercedes A-Class E-Cell electric car. It has a range of 200 kilometers (124 mi), and a torque of 290 Nm. The 36 kWh battery pack contains over 4,000 lithium-ion batteries. As of December 2011, Tesla Motors sold 500 battery packs and chargers to Mercedes for the Class A E-Cell program.

Mercedes B-Class EV

In the second quarter of 2014, Tesla Motors started the delivery of batteries, engines and propulsion systems for the Mercedes B-Class EV.

Daimler Smart

In early 2008, Tesla began working with Daimler AG on engine components for the electric version of the Smart. Until December 2011, Tesla sold 2,100 battery packs and chargers for the electric Smart ForTwo. In 2014, Daimler ended supply contract with Tesla and sold its shares for 780 million USD.

Toyota RAV4 EV

In July 2010, Tesla Motors and Toyota signed an agreement to start development of a second generation Toyota RAV4 EV. In the summer of 2012, the vehicle started selling for $51,000. Tesla has a $100 million contract to supply electric motors, power electronics components, lithium-ion battery packs, one-gear gearboxes, and software. These components are similar to those of the Tesla Model S. The maximum speed is 100 miles per hour (161 km / h). Acceleration from 0 to 60 miles per hour (97 km / h) is 7 seconds. Normal range is 100 miles (161 km). Tesla Motors activities regarding the RAV4 program came to an end in the third quarter of 2014.

Freightliner Custom Chassis

Freightliner Custom Chasis is a subsidiary of Daimler AG that manufactures chassis to later be built as delivery vans. It has an electric version MT E-CELL All-Electric Delivery Van with a 120 kW motor that has a range of up to 100 miles (161 km). The battery fully recharges between 6 and 8 hours. It reaches a speed of 65 miles per hour (105 km / h). You can save on fuel up to $15,000 per year compared to similar vans. Tesla provided them with the battery pack, motor, power electronics and software.

Headquarters

Tesla is based in Palo Alto, California. Centralizes research and development departments, and performs prototypes and tests of batteries, motors, power electronics and software. It is 350,000 square feet (32,516 m²) and is leased to Tesla. In Hawthorne, California, it is leased from a 132,250 square foot (12,286 m²) facility dedicated to engineering and design services. In Maidenhead, UK, it is leased from 8870 square feet (824 m²) facility dedicated to administration, sales, service and advertising.

Factories

The Tesla Motors factory is in Fremont, California. It was originally owned by GM and closed in 1982. In 1984, it was reopened and jointly operated by Toyota and General Motors. It was known as NUMMI (New United Motor Manufacturing Inc.). The plant operated for 25 years producing 8 million vehicles until GM retired in 2009. Toyota Corolla production in North America moved to Cambridge, Ontario, Canada. As of May 2010, NUMMI manufactured an average of 6,000 vehicles per week.

Tesla took possession of the plant on October 19, 2010, and opened it on October 27. On June 22, 2012, the first Tesla Model S was delivered in a special presentation at the factory. In 2010 Tesla bought most manufacturing equipment for $42 million, including body presses and plastic injection machines. Tesla Motors bought NUMMI and Toyota with significant discounts of more than $17 million in manufacturing equipment and parts. The Obama administration granted a federal loan of $465 million with which the company began to recondition the factory.

The Tesla factory performs sheet metal cutting and pressing, plastic injection, body assembly, painting, battery pack manufacturing, final assembly and quality control testing. Most of the stamped and aluminum parts and over 90% of the Model S plastic parts are produced in-plant. More Model S parts are manufactured at the plant than were made for the Toyota Corolla previously produced at the factory. The Tesla Model S has more than 2,000 parts that are purchased from more than 200 external manufacturers. The factory walls and floor were painted white and many skylights were installed on the ceilings for more natural light.

In June 2012, Tesla Motors employed more than 2,000 workers. In June 2015, it had 12,000 employees. As of September 30, 2014, none of its employees belonged to any union.

Gigafactory 1

The Gigafactory 1 Tesla is a huge factory of lithium ion batteries that began building in Reno, Nevada in September 2014. It began production in 2017.

The construction cost was around USD 5 billion. When the factory is fully operational, Tesla hopes to get a 30% reduction in the production cost of batteries for electric cars. By 2020, it hopes to produce batteries for 500,000 Tesla cars a year. The models equipped with the batteries produced in Tesla’s Gigafactory 1 are the Tesla Model S, Tesla Model X, Tesla Model 3 and Tesla Model Y.

It offers about 6,500 direct jobs and about 16,000 indirect ones. Hiring is primarily for people of the state of Nevada and especially veterans. The state of Nevada had a population in 2012 of 2,758,931. In 2010, the city of Reno had 225,221 inhabitants. Nevada Governor Brian Sandoval said in September 2014 that the impact of Gigafactory 1 in Nevada would be $100 billion over 20 years. When it is in full operation, it will compose 4% of the GDP of the state of Nevada. The Governor expected a return of $80 for every $ invested by the state of Nevada in incentives to Gigafactory 1.

A total of 35 GWh of lithium ion cells will be produced at the plant for the needs of the Tesla factory in Fremont and 15 GWh of lithium ion cells for stationary battery packs (for use in buildings). Elon Musk said the factory would have a diamond shape oriented north to improve the solar panels cover, and easily locate all components and GPS equipment. The factory will be energy self-sufficient. It will produce its electricity with photovoltaic solar energy and other renewable energies such as wind or geothermal. It will try to minimize the environmental impact. The plant will also recycle used battery packs.

Location:

It is at the Reno Tahoe Industrial Center at 2641 Portofino Drive, Reno, Nevada ,United States. It occupies an area of 929,030 square meters. The distance between the Tesla factory in Fremont, California and Reno, Nevada is about 330 km. On September 3, 2014, Nevada Governor Brian Sandoval and Elon Musk announced that the location of Gigafactory 1 would be in Nevada.

Gigafactory 2

Tesla’s Gigafactory 2 is a solar panel factory leased by Tesla in Buffalo, New York, USA. The factory is owned by New York State and was built on the grounds of a former steel mill between 2014 and 2017.

In 2013, the grounds of the Gigafactory 2 were planned as a business incubation center for clean energy. SolarCity acquired Silevo in 2014 and merged with Tesla two years later. In partnership with Panasonic, it began manufacturing photovoltaic modules in 2017 using photovoltaic cells imported from Japan. It started its commercial module production in 2017. In 2018, SolarCity started manufacturing individual solar cells. After the start of the Gigafactory 1 near Reno, Nevada in 2016, Tesla began referring to the Gigafactory SolarCity as Gigafábrica 2.

Gigafactory 3

Tesla Gigafactory 3 is a Tesla factory in Shanghai, China.

It produces batteries and vehicles; Tesla Model 3 and Tesla Model Y, with an initial production of 250,000 cars per year.

Construction began in December 2018. The plant began initial production of Tesla Model 3 cars in October 2019

Gigafactory 4

After several years announcing a factory in Europe without deciding the country where it would be built. In November 2019, it was announced that it will finally be done in Germany, near Berlin. Its under construction in 2020 with the intention to start operating at the end of 2021.

Service centers

Tesla Motors has its own dealers. In July 2010 Tesla hired executive George Blankenship as Vice President of design and development of dealers. He had previously worked at Apple and Gap. Most Tesla centers have an attached workshop. In some markets Tesla will install separate stores and workshops.

Tesla offers a home service called “Tesla Ranger mobile service” in which it charges the customer a fixed price per mile of travel. Owners of a Tesla vehicle can send diagnostic data via mobile phone or on a memory card. This allows many problems to be diagnosed and repaired before physically looking at the vehicle. When maintenance or repair is necessary, the customer makes an appointment at a Tesla workshop. The Tesla Rangers can perform many repairs on their travels, such as annual reviews, software and firmware updates, change of electronic modules and some mechanical components. If the repair is major and requires a lift the vehicle is taken to the nearest Tesla workshop.

In 2012, Tesla had Service Centers and / or Service Rangers in Chicago, Copenhagen, Dania Beach, Denver, Eindhoven, Hong Kong, Los Angeles, Menlo Park, Milan, Munich, Newport Beach, New York, Oslo, Paris, Seattle, Sydney, Tokyo, Toronto, Washington DC, London and Zurich. By March 2018, there were 339 shops and service centers worldwide.

Recharge technology

Superchargers

On September 25, 2012, Tesla introduced its direct current superchargers. Tesla installs them in the rest areas of the roads, so that while the driver rests, the car recharges. Several charging poles with a maximum shared power of 120 kW were installed at each location for each two poles.

These recharges were free for all early Tesla Model S and Model X indefinitely. On April 24, 2014, Tesla commissioned its 100th Rapid Charge Station.

In March 2019, Tesla released an over the air update that removed the 120 kW limit from vehicles and allowed them to charge up to 145 kW across the supercharger network. In March 2019, Tesla announced the Supercharger V3 version in which using 1 MW PowerPacks and liquid-cooled cables; it achieved recharge powers of up to 250 kW on each pole.

In March 2019, it also launched an update with which it conditions the temperature of the battery when the vehicle is routed to a supercharger so that the average charging time is reduced by 25%.

There are Chademo quick charger adapters to Tesla connectors, offering up to 50 kW direct current.

Battery Swap

On June 20, 2013, Tesla presented the battery swap program for the Tesla Model S. The driver goes to a Tesla exchange station where he places the car on a pit. A robotic system removes the screws that hold the battery pack to the body, removes the discharged pack down, places a loaded pack, and tightens the screws to the specified torque. The driver does not get out of the vehicle during the 90 second process.

In the presentation of the system it was compared live with the refueling of a car at a gas station with a high supply flow (38 liters per minute). From the moment the driver got out of the car until he started again, 4 minutes and 7 seconds passed. During that time the batteries were changed to two Tesla Model S. The battery exchange of the first Tesla Model S took place in 1 minute 13 seconds and in the second in 1 minute 33 seconds.

In December 2014 Tesla Motors started a pilot battery exchange program in Harris Ranch, California, alongside a supercharger. This program aims to test technology and service demand. The exchange process takes about 3 minutes and the cost is similar to filling a gas tank in a car of its range. Finally, after a trial period in which customers were able to test the system, Tesla decided to end the project because only 5 people of the 200 invitations deployed by the company went to use the station. Elon Musk decided that it was not feasible to continue with the project.

Patents

On June 12, 2014, Elon Musk announced that he was releasing his patents so that they could be used in good faith for the construction of electric vehicles and to advance electric vehicle technology. In 2014, less than 1% of the vehicles produced were electric.

In 2014, the annual production was close to 100 million vehicles and the total fleet was about 2 billion vehicles. Tesla believed that applying the open source philosophy to his patents would strengthen him and not weaken him.

Partners

Tesla Motors manufactures and sells its cars, but unlike other manufacturers, it also operates as an original equipment manufacturer (OEM). It makes components for electric vehicles that other manufacturers can buy and use under their own brands. Tesla had collaborations with Daimler AG and Toyota. It also works closely with Panasonic as a strategic partner in battery research and development.

Daimler AG

In May 2009, Daimler AG acquired almost 10% of Tesla Motors shares for an amount of about $50 million. On December 31, 2011, the subsidiary of Daimler AG Blackstar lnvestco LLC owned 8,113,215 shares of Tesla Motors. Tesla Motors and Daimler AG agreed to cooperate on battery systems, powertrains for electric vehicles and vehicle projects. As part of the collaboration, Dr. Herbert Kohler, Vice President of E-Drive and Future Mobility at Daimler AG, had a seat on the Tesla Board of Directors. In July 2009, AABAR AD bought 40% of the shares it owned in Tesla Motors from Daimler AG. In 2014, Daimler terminated the supply contract with Tesla and sold its shares for $ 780 million.

AABAR AD

AABAR AD is an investment company controlled by IPIC (International Petroleum Investment Company), which is owned by the Government of the Emirate of Abu Dhabi. IPIC is one of the means to invest the oil wealth of Abu Dhabi, which is one of the largest oil exporters. In March 2009, AABAR AD bought 9% of Daimler AG shares. In July 2009, AABAR AD bought 40% of the shares from from Daimler AG, it owned in Tesla Motors.

Toyota

In July 2010, Tesla Motors sold 2,941,176 shares to Toyota at a price of $17 per share. The sale was 50 million.

Panasonic

On January 7, 2010, Tesla Motors and Panasonic announced that they would collaborate on the next generation of batteries based on the model 18650 electric vehicle lithium ions. The agreement is part of an investment of Panasonic 1000 million in 3 years to research, development and production of lithium ions. Tesla may continue to use batteries from other suppliers.

In April 2010, Panasonic Energy Company’s President Naoto Noguchi, presented JB Straubel, CTO of Tesla with the first lithium-ion batteries produced at the new factory in Suminoe, Japan. This factory started production of 3.1 Ah batteries, which had the highest energy density on the market at that time. The factory produces more than 300 million batteries a year.

On November 5, 2010, Panasonic invested $30 million in Tesla Motors to accelerate the expansion of the electric vehicle in the automotive market. In October 2011, both agreed to supply batteries for more than 80,000 vehicles.

Conflicts

Fisker Automotive

On April 14, 2008, Tesla Motors sued Fisker Automotive, alleging that Henrik Fisker stole design ideas and confidential information regarding the design of electric and hybrid cars and that he was using that information for the development of the Fisker Karma, which had been presented in January, 2008, at the North American International Auto Show. Tesla had hired Fisker Coachbuild and paid $800,000 for the body and interior design of the WhiteStar sedan (Tesla Model S), but Elon Musk canceled the proposed design for being inferior to what was contracted. On the date of the contract, Tesla was not informed that Fisker was working on a similar hybrid to the Tesla Model S.

On November 3, 2008, Fisker Automotive Inc. released a press release stating that an arbitrator had issued an award in favor of Fisker Automotive Inc. and against Tesla Motors. Tesla said the award was binding and would not proceed with the case.

Magna International

In March, 2008, Magna International sued Tesla Motors for $5.6 million for failing to receive payment for services provided in designing a transmission for the Tesla Roadster. Tesla reverted to an earlier X-Trac manufactured transmission design in which the first gear was retired on the standard Roadsters.

Founders of Tesla Motors

On May 26, 2009, Martin Eberhard filed a lawsuit against Elon Musk for slander, defamation, breach of contract on who could be called founders of Tesla Motors.

The San Mateo County Superior Court judge ruled that Tesla Motors was created by a team of founders: Elon Musk, JB Straubel , Martin Eberhard, Marc Tarpenning, and Ian Wright.

Top Gear

Tesla Motors sued for malicious misrepresentation and libel, the BBC Top Gear car show, in relation to the 2008 episode in which Jeremy Clarkson complained about a range of only 55 miles (89 km) from the Tesla Roadster, before showing how they were pushing the car to the garage, supposedly due to exhaustion of the batteries. Tesla Motors claimed that neither of the two used Tesla Roadsters fell below 20% in battery capacity during Top Gear testing, and that the scene was scripted beforehand.

Clarkson also claimed that he had suffered a brake failure when it was a blown fuse according to Tesla, and that an overheating of the electric motor caused it to stop when there was no such heating according to Tesla.

On October 19, 2011, the High Court in London rejected the libel lawsuit arguing that Top Gear was an entertainment program.