Spanish carmaker SEAT said it is working with HP to use 3D printing technology to make automotive parts for its high-performance racing unit, Cupra.

According to reports, a group of innovative engineers at Spanish automaker SEAT’s high-performance racing unit CUPRA is revolutionizing the way cars are developed by printing auto parts. The department is using the most advanced multi-nozzle fusion technology to process parts in a fast and efficient manner.

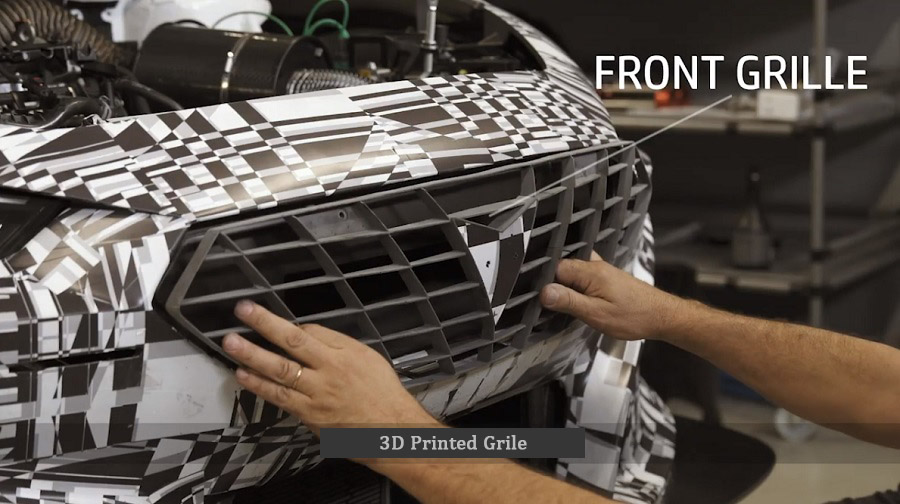

On the new Leon Competición racing car, Cupra engineers used 3D printing technology to make the car’s door mirrors, air intakes, and radiators. This technology allows SEAT to reduce vehicle fuel consumption while increasing vehicle stability, speed and safety, all three of which are critical not only for racing cars but also for normal cars.

It takes about 20 hours to print a mirror, but CUPRA can print six sides at a time, allowing the team to create different designs at the same time. It also means that CUPRA can quickly test different prototype parts in the wind tunnel to find out the aerodynamics.

When the printed parts are used in a controlled environment, they will be installed on the vehicle and face high winds exceeding 180mph. At the same time, the sensors will study the impact of such parts on the surface of the car. The car’s resistance data will be displayed on the screen, and engineers and designers will compare the resistance data results of different printed parts.

Because the smallest differences in components can have a huge impact on the car, it is important that 3D printed components can reduce fuel consumption while increasing stability, speed, and safety.

“For the new Cupra Leon Competición, we modeled the steering wheel’s central control module, hood vents, door mirrors, brakes, and water-cooled inlets. Our goal is to model a lot of parts completed in a short time, you can quickly test a variety of designs, and this technology allows us to respond quickly to any changes in the design process. The more types of parts we test, the more it will allow us to make progress faster.”

The final development of 3D printed parts took place on the racing track, and CUPRA tested the Leon Competición model at the Portimao track in Portugal. Until now, CUPRA has printed parts for Leon Competición. The car has a speed of 180mph, produces 335bhp and is equipped with a 2.0 L engine. The design is inspired by SEAT’s new Leon family E-Racer, which is an electric vehicle, acceleration time of 100 kilometers only needs 3.2 seconds.

Currently, Cupra has announced the printing and testing process for this project in cooperation with Hewlett-Packard Company (HP).