• Aachen’s Ford Research and Innovation Center is involved in the development of a new air purification breathing apparatus that will be manufactured at the Ford plant in Vreeland near Flat Rock, Michigan, in the USA.

• In the wake of the Corona crisis, Ford is building a production facility at its British site in Dagenham to manufacture parts for respirators.

• The conversion of a warehouse into a manufacturing facility took only three weeks, normally such a setup would have taken a whole year.

• Hundreds of volunteers manufacture components and screens that will later become part of the assembled ventilators, including using virtual reality.

The German Ford Research Center in Aachen (Ford Research and Innovation Center) worked on the development of a new air purifying respirator (PAPR) that is located at the Ford plant in Vreeland near Flat Rock, Michigan / USA is manufactured. With the so-called “Project Apollo” Ford wants to contribute to reducing the spread of the corona virus. As part of this international project, Ford manufactures personal protective equipment; At the same time, the company supports local and national initiatives to provide ventilation equipment and protective masks.

For healthcare professionals, the air-purifying respirator includes a hood and face mask, while a battery-operated ventilator and highly efficient filter system provide 99.97 percent filtered air supply for up to eight hours. The engineers who worked on the Ford Interior Air Advanced Filtration System provided know-how in filter design to develop the filter used in the respirator in clinical quality.

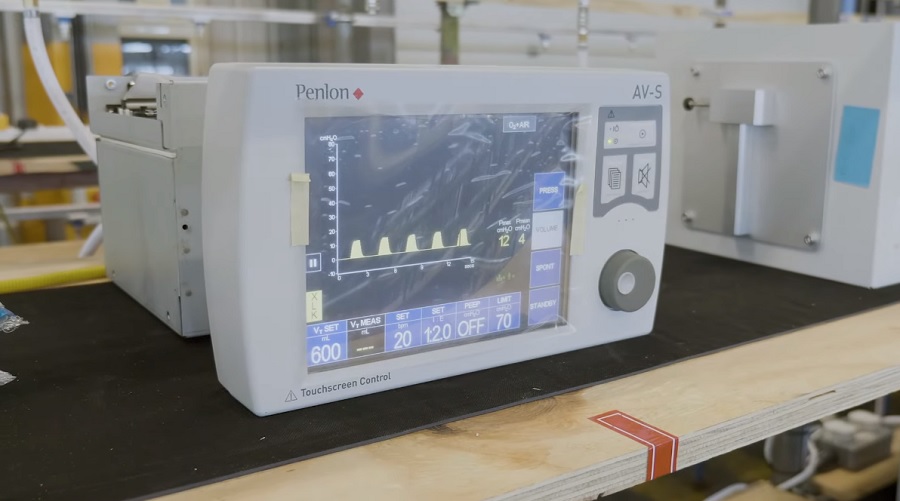

At the UK site in Dagenham, Ford manufactures ventilator parts. For this purpose, a warehouse was converted into a production facility in a record time of just three weeks. The production is carried out in cooperation with the VentilatorChallengeUK Consortium – a cooperation between leading technology providers for the delivery of a total of 15,000 urgently needed Penlon Prima ES02 ventilators, which the National Health Service in Great Britain (NHS) uses for the treatment of seriously ill COVID-19 patients.

“They worked hard day and night. The ingenuity and commitment of our team was just great. The result of our efforts shows how a crisis can bring out the best in us, ”said Graham Hoare, Chairman, Ford of Britain. “The employees involved sacrificed a lot of time that they would otherwise have spent with their families. And they were always ready to learn something new to help create these lifesaving devices. It makes me very proud to be part of this team”.

The conversion of a warehouse on the factory premises into an ISO 9001 certified production facility required existing systems to be converted and a production line for component housings and 8.4-inch televisions to be built, which are an important part of the units that were later fully assembled. The Ford volunteers involved, which include technicians and engineers from a wide variety of departments, use 3D printing processes to produce key components for around 200 workstations that meet the distance requirements. In total, more than 650 employees will work in three shifts in the plant with full production.

Ford is part of a consortium that also includes companies like Airbus, McLaren, Penlon and Siemens. For the collaboration with Penlon in Oxford, UK, the Ford team uses virtual reality headsets (HoloLens 2), with which technicians and specialists can exchange technical information in real time, which is displayed to the wearers of the associated VR glasses as holograms.