Gasoline, diesel, four- and six-cylinder, direct injection or not: the variety of combustion engines is enormous, but the electric motor has a lot of power in a small space.

A few magnets, some copper and a shaft for power transmission: Compared to a modern diesel or gasoline engine, the structure of an electric motor is astonishingly simple. In principle, the machines in the electric car all work with similar technology. In the details, however, there are a few differences that you should be aware of as a car buyer. A little engine knowledge.

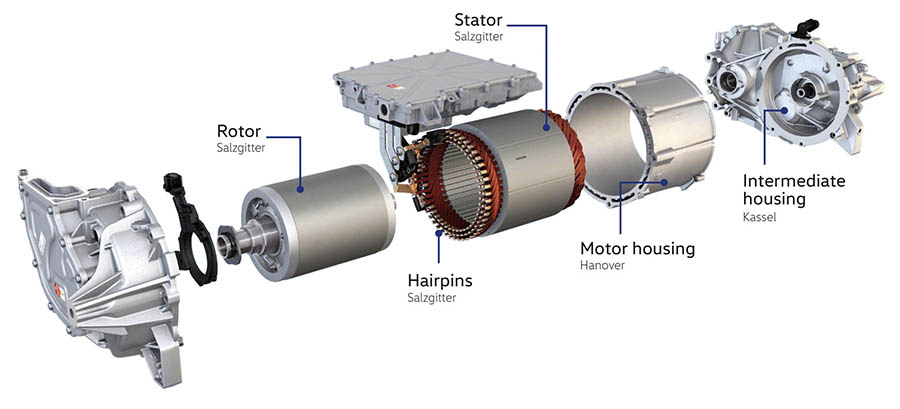

Three sub-types of e-machines have established themselves in cars today. Almost all of them work with alternating current or three-phase current. What they all have in common is the basic structure of a fixed, magnetic stator and a moving rotor, which ultimately also sets the car’s wheels in motion.

In order for it to rotate, it must have a magnetic field that is attracted by the magnetic field of the stator. Just before they meet, the field of the stator moves on, forcing the rotor to move on as well.

Most often the so-called permanent magnet synchronous motor (PMSM) now takes over the drive work in the electric car. “Permanent”, because the rotor has its own magnets that generate a permanent field.

This is not the case with the separately excited variant (FMSM). There the magnetic field is temporarily generated by electricity – i.e. by an electromagnet. This is significantly cheaper to produce than using permanent magnets made from rare earths, which is why this technology is particularly interesting for more price-sensitive e-cars. Or for those who do not depend on extreme performance. So it’s no wonder that it was the developers’ first choice in small cars like the Renault Zoe. And the current Smart also relies on the technology.

Other manufacturers see motors with the more expensive permanent magnets as the better alternative. Because it has advantages in terms of efficiency and power density. It is precisely these points that make the permanently excited synchronous machine interesting for many manufacturers despite the higher costs. Because it enables a greater range with the same battery capacity thanks to its economical use of energy and also requires comparatively little installation space.

This is why PMSM can be found in almost all hybrid cars that also have to accommodate an internal combustion engine under their narrow hood. And in much of the current pure electric cars such as the BMW i3, Porsche Taycan and VW ID.3.

What Audi and Tesla are betting on

In addition to the two types of synchronous motors, there is a third variant of the e-machine: the asynchronous. While the magnetic fields of the strator and rotor run in the same cycle with synchronous motors, the rotor with asynchronous motors (ASM) lags slightly behind. The very robust overall concept is a bit simpler and does not require complex controls or expensive permanent magnets.

In return, however, the ASM lacks efficiency. It is also comparatively heavy and loud. But it has one big advantage: it can be deactivated at any time. If the current is switched off, it runs free-wheeling and does not consume any energy. The permanent magnets in the PSM, on the other hand, cannot be switched off. If the engine is not actively driving the car, it acts like a dynamo instead and recuperates permanently.

And that is not desired, because this form of electricity generation is only efficient if the energy would otherwise be lost in the form of heat when braking. However, this is not the case with smooth sailing on the motorway – there the energy is used for locomotion. The ASM therefore plays an important role, especially in expensive e-mobiles for long distances.

Another advantage comes into play here: Because the asynchronous motor can work with overload for a short time and thus generate a boost effect – this is particularly interesting for the sporty, premium class e-mobiles. The ASM can therefore be found among others at Audi E-Tron and Mercedes EQC. Even Tesla puts him in Model S and X is a, now in combination with the efficient especially off the highway PPPs. In the future, this kind of division of labor should also be found in other models. However, probably more in the upper price range.

A candidate with a future in the electric car could be the so-called reluctance motor, which works on a completely different principle than magnetically excited machines. It makes use of the phenomenon that every system strives for minimal magnetic resistance (reluctance). Because the rotor works without permanent magnets or electromagnets, it is very inexpensive to manufacture. However, the engine is loud and not very smooth.

So the electric motor technology is not quite as monotonous as it looks at first glance. And there is likely to be even greater development steps in the future, especially in terms of costs.

Bmw I3 has an externally exited synchrous machine.

Tesla is switching to PESM